I wonder if coach Vince Lombardi was a lean practitioner. Over 60 years ago he effectively harnessed the fifth lean principle when he encouraged his football team saying, “Perfection is not attainable, but if we chase perfection, we can catch excellence.” Sure sounds like a lean mindset.

The fifth lean principle, pursue perfection, is really that, a mindset. It is a discipline that helps teams develop habits around constantly looking for better ways to serve their customers’ needs. So, how do we apply this chasing and catching mindset to the system that organizations use to find, train, and retain people?

Define What to Chase

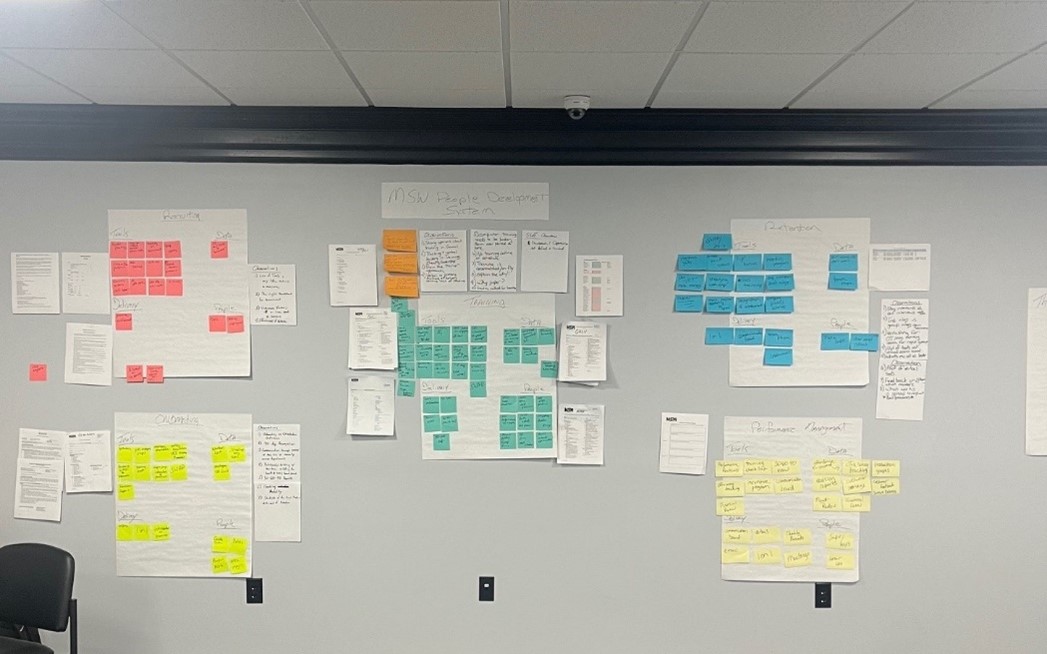

Applying the second lean principle helps determine the current state of the people development system. In this case via the Talent Stream Map. From this current state map, we can begin to envision and construct a future state map. If we were to actually capture perfection, what would that look like? Obviously, there’s a need for a realistic vision, but this is the chance to dream big and set stretch goals. Ultimately, what type of people development system do we want?

Once the future state is articulated, the team can rally around the vision, understand the direction, and see the challenges ahead.

The duration of the chase

My team uses the word optimization to capture the spirit of continuous improvement. Admittedly, it’s semantical, but useful and it makes a nice acronym. Apparently, we get extra points for catchy acronyms. The idea is the same, we look for ways to make the system better, more efficient, and more effective.

We see at least three levels of optimization:

- System functionality. How well is the PDS working? Can we improve the connections between the five processes? Is data being collected and used effectively?

- People centeredness. Is the system really focused on the people it serves? Can we expand our definition of development? Does the system help people adapt to change?

- People + machines (Industry 5.0). Does the PDS help people become technology savvy (where tech might be applied, how to use data, etc.)? Does the PDS promote applied systems thinking to all stakeholders? Is the PDS capable and ready to aid in the transition into I5.0?

The important point here is that, like other systems, there are many opportunities to improve the PDS, so the journey is a long one. Done well, it can be a very fruitful one as well.

Determination in the chase

We use maps to go on journeys and journeys take time. Leaders and stakeholders of the PDS help keep the momentum of continuous improvement by constantly pointing toward the future state and reminding the team of the value of striving in that direction.

As easy, early gains give way to slower and more hard-fought progress, the determination to keep pressing forward is vital. Resolute leaders and effective communication are needed.

A chasing and catching culture

Coach Lombardi may not have been a lean guru, but he certainly understood the power of building a culture focused on constantly pushing the limits. He wanted his whole team to adopt high standards and to strive to reach a level of performance that was only possible if they reached those standards.

The fifth lean principle serves as a cultural anchor. When the whole team is fully committed to continuous improvement, the chasing of perfection becomes a way of life within the organization. Appling this type of lean thinking to the PDS can help stakeholders to catch a level of excellence that will benefit the entire organization.

Wrapping up the principles

Over these last six posts, we’ve explored how to apply lean thinking to an organization’s internal workforce development efforts.

The five principles of lean follow a logical thought process. We identify what our customers want (first principle); we know our system (second principle); we fine-tune and make our system efficient (third & fourth principles); and, from the fifth principle, we pursue the perfect system.

Although the PDS is a non-linear system that can be difficult to see in operation, these five principles are still useful when trying to find ways to reduce waste, find efficiencies, and generally make improvements. If your team hasn’t applied these guiding principles to this especially important system, try it. And then share what you learn!